Contaminants

ver the last two years, individuals and businesses have started to pay a lot more attention to keeping their spaces clean—something that, because of COVID-19, took on more importance than ever. And while it’s become commonplace to see cashiers wiping down grocery store conveyor belts and restaurant staff disinfecting seating areas, there are some industries that have always had to put cleanliness and sanitation first for the health of their employees and the general public.

To this end, companies in a variety of fields—from gas stations to energy companies to cruise lines to military bases to air cargo companies and more—hire HSE (health, safety, and environment) specialists or environmental services companies to keep their facilities clean. Not only is this work challenging—imagine the labor involved in cleaning a 24,000-gallon fuel tank—but it can also be dangerous.

“Our job is to find safe ways to perform work on unique jobs in hazardous conditions,” explains Brock Nelson, a field foreman for US Ecology, of the company’s many responsibilities that range from cleaning small or large fuel tanks to dealing with paints, PCBs, POL (petroleum, oil, and lubricant) contaminants, and hazardous waste.

“We also provide a safe and environmentally friendly way to dispose of and recycle waste streams with the least amount of impact on the environment and clean up spills to help restore the environment back to its original state,” adds US Ecology’s Operations Manager Zach Hamilton.

Contaminants

ver the last two years, individuals and businesses have started to pay a lot more attention to keeping their spaces clean—something that, because of COVID-19, took on more importance than ever. And while it’s become commonplace to see cashiers wiping down grocery store conveyor belts and restaurant staff disinfecting seating areas, there are some industries that have always had to put cleanliness and sanitation first for the health of their employees and the general public.

To this end, companies in a variety of fields—from gas stations to energy companies to cruise lines to military bases to air cargo companies and more—hire HSE (health, safety, and environment) specialists or environmental services companies to keep their facilities clean. Not only is this work challenging—imagine the labor involved in cleaning a 24,000-gallon fuel tank—but it can also be dangerous.

“Our job is to find safe ways to perform work on unique jobs in hazardous conditions,” explains Brock Nelson, a field foreman for US Ecology, of the company’s many responsibilities that range from cleaning small or large fuel tanks to dealing with paints, PCBs, POL (petroleum, oil, and lubricant) contaminants, and hazardous waste.

“We also provide a safe and environmentally friendly way to dispose of and recycle waste streams with the least amount of impact on the environment and clean up spills to help restore the environment back to its original state,” adds US Ecology’s Operations Manager Zach Hamilton.

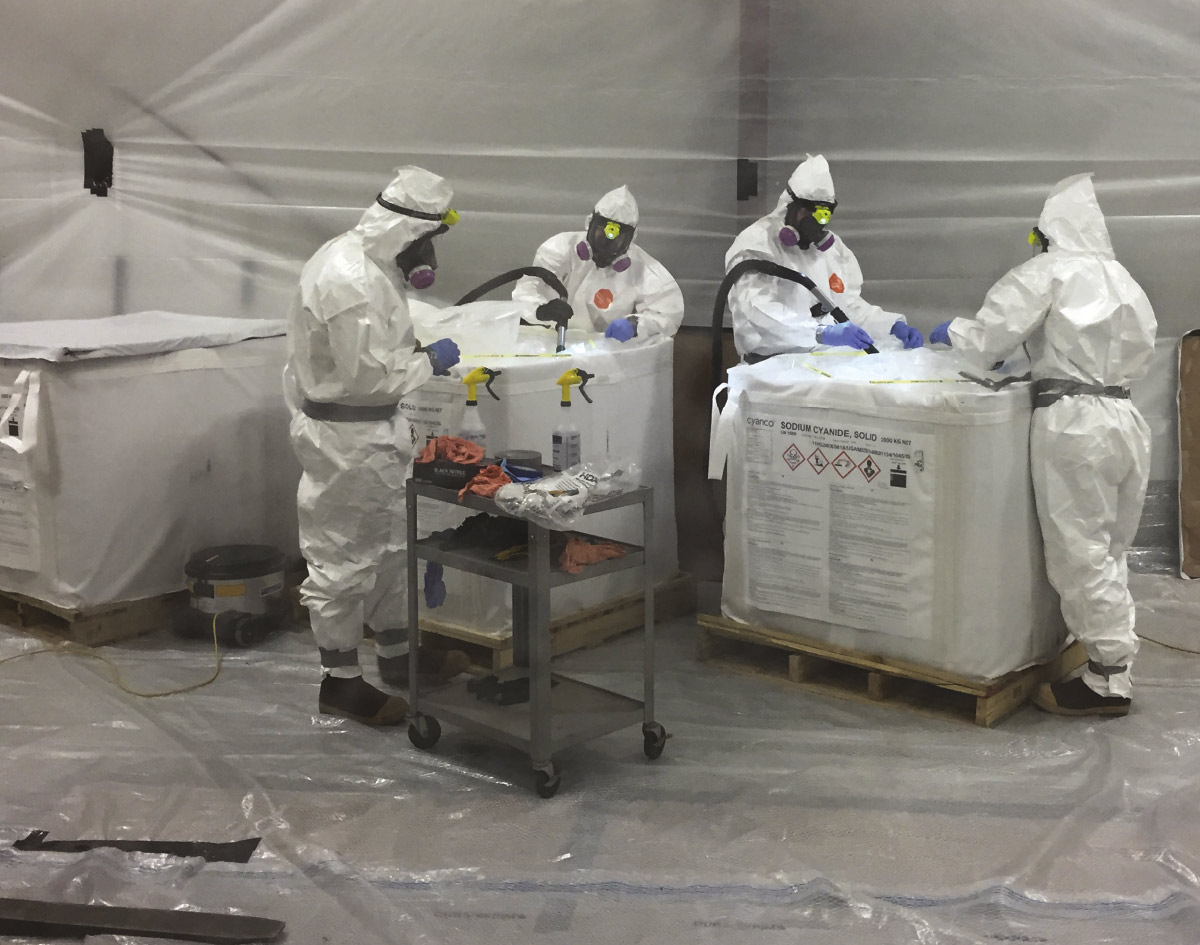

“There are a lot of potential hazards on job sites, but probably the biggest issue is exposure due to equipment or PPE [personal protective equipment] failure,” says Hamilton. “Tears and punctures in PPE can lead to inhalation hazards, as well as the risk of absorbing toxins through the eyes and skin.

“This is why our health and safety measures are so stringent—anything that we can think of that could happen, we prepare for,” he adds.

Pre-planning is key when it comes to identifying and mitigating risk.

“Health and safety is our top priority, so before every task or job, a job hazard assessment is filled out, and we hold tailgate meetings so that everyone involved has an understanding of the hazards and the plan before the work day starts,” says Nelson.

“Our health and safety professionals evaluate each job before sending anyone in to do the work, so all hazards are considered before work is performed,” he continues. “And we all have the authority to stop work at any time to reevaluate tasks if someone feels something has changed during the job.”

If employees are working in an area that is known to have heavy concentrations of lead, for example, employees are monitored throughout the entire job and are pulled from the site if increased lead elevations are detected.

“All of our employees also undergo a yearly physical to ensure their health and to make sure that nothing has changed with that employee,” adds Hamilton.

While some hazards—such as fuel spills—can easily be seen, others, like the COVID-19 virus, cannot.

“At the beginning, everyone was kind of panicked,” says Nelson of the virus that required businesses to decontaminate their facilities and institute strict cleaning protocols to keep employees safe. “We treated it like any other biological hazard, wearing full face respirators, hazmat suits, and rubber gloves—and making sure that all of the seams were closed.”

Wearing full PPE, US Ecology staff sprayed down floors and high-touch areas such as bathrooms with Shockwave, an EPA-registered disinfectant, sanitizer, and cleaner designed for use on various surfaces subject to microbial contamination. It also installed fogging machines for commercial warehouses to decontaminate larger areas. After decontamination, the company followed strict CDC protocols to insure that the contaminated PPE was disposed of properly.

This caution extended to US Ecology’s own offices, where social distancing was required and training class sizes were limited.

“We did have to change the way we practiced using equipment in the training classes; you couldn’t have one person using a mask and then passing it on to the next guy,” says Nelson, who added that they instituted more stringent cleaning procedures and also checked everyone’s temperature daily.

While things have calmed since the start of the pandemic, US Ecology still receives client requests to keep facilities COVID-19-free. “At the pandemic’s peak, we were getting calls around the clock,” says Nelson. “Now we get one every couple of weeks to provide decontamination services of this nature. But dealing with a biological hazard at that level—that was definitely a first for us.”

US Ecology

US Ecology

“Depending on what the issue is, we determine how best to attack it,” says Nelson, adding that in a chemical spill, for example, the toxin must first be identified.

“Most transport companies carry manifests that have everything documented, so Safety Data Sheets [SDS] are the first identifier that we ask for when we show up,” says Nelson of these OSHA documents that are required for hazardous products or chemicals. The SDS includes information on the properties of each chemical; the physical, health, and environmental health hazards; and protective measures and safety precautions for handling, storing, and transporting them. It also includes emergency control measures.

“For example, if a trailer comes in leaking a clear liquid, we would first ask for all of the safety data sheets for the trailer, and then compare those listings with what we can see and monitor,” says Hamilton. “If there is more than one chemical on the trailer, this helps us eliminate chunks of other hazards. If the liquid is not identifiable, or there is no SDS, we go in under a much higher level of PPE.”

Whether dealing with a planned or unplanned event, the company follows rigorous protocols when working at a site. This includes utilizing 5 gas meters, which detect combustible gases in LEL (lower explosive limit) and/or volume percentage range, oxygen, carbon monoxide, carbon dioxide, hydrogen sulfide, sulfur dioxide, ammonia, chlorine, and VOCs (volatile organic compounds), among other hazardous materials.

“This helps us not only determine what we’re dealing with but how long we can be in the area based on exposure limits, what type of air or ventilation system we need to use—such as pneumatic or explosion-proof fans—what PPE we need to wear, and any other type of specialized equipment that is required for that contaminant,” says Nelson.

In some cases, technology can even be used to clean a site without requiring a human to be placed in harm’s way. The GamaJet GobyJET portable pump system, for example, is a “manless” entry cleaning system that uses global indexing patterns to provide 360 degree tank cleaning, eliminating the need for confined space entry.

Technology has also helped with the equipment that HSE professionals wear while working onsite; while self-contained breathing apparatus air tanks used to be heavy and hold only 30 minutes of air, they are now lighter and have increased air capacity. Meters are also now more user-friendly, work more quickly, and are more reliable than previous incarnations.

“Depending on the type of waste, it goes to various disposal facilities throughout the country such as landfills, incinerators, and recyclers,” says Hamilton, adding that this waste is transported by highway, over water, and sometimes by air. “All shipments are made using DOT-approved shipping papers such as bill of ladings, hazardous waste manifests, non-hazardous waste manifests, and dangerous goods declarations for air transport, depending on how it is regulated.”

While some materials must be completely disposed of, others, like fuel and oil, can be recycled.

“Because technology has changed a lot, we are now able to recycle things that we couldn’t before,” says Nelson. “For example, we use Dolphin separation equipment to drop the sludge and water out of oils so that we can turn around and sell it as burner fuel to asphalt companies and shops that want to use it for heating.

“We try to recycle whatever we can; it really depends on the waste stream,” he continues, adding that through its distillation plant, the company is also able to recycle the glycol antifreeze that it collects.

US Ecology

US Ecology

“We fill out a manifest that identifies the waste characteristics and constituents and also has the generator and the disposal site listed,” says Hamilton. “Shipping papers are used to help track the waste, and at each stop the transporter needs to sign it. Then the original manifest is sent back to the generator so that they know where their waste went, from cradle to grave.”

With so many issues to keep track of, even companies that have their own HSEs in-house often look outside for help.

“A company may have one or two people, but if something ends up happening, such as a larger spill event, they’ll call us in to assist. Or if they are struggling with a solution, they bring us in to give them options for disposal or industrial cleanings,” Hamilton explains. “Sometimes, if a company is working with the state on an issue, the state may also recommend that they get ahold of us to make sure that the site is cleaned to their high standards.”

When hiring outside HSEs or environmental services companies, there are several factors that a company should look for including experience, the ability to provide cost-effective solutions, an exemplary safety record, and the expertise to be able to come up with various plans of attack.

“It is also important that companies have the capability to work in the more remote parts of Alaska and the United States and in all weather conditions,” says Nelson. “They also need to have the available response equipment for spills, rescues, and planned projects,”

He adds, “This is a dangerous line of work and it can be very expensive, so you have to make sure that you’re hiring a company that has the experience and knowledge to do it correctly.” ![]()