n Alaska, metal fabrication takes many forms, from making the smallest components like screws, nuts, and bolts to creating ready-to-assemble, 350-person camps. In the construction industry, the need for companies that can build machines and structures from raw metal materials is constant, whether the job requires building a single-family home or crafting control panels to guide the oil that runs through pipelines.

The fabrication process, which can include cutting, burning, welding, machining, forming, and assembly to create the final product, requires that most companies have their own metal shops to centralize these tasks. And while some fabricators provide ready-made materials for more generalized construction needs, others specialize in extremely specific, custom-made work.

NANA Construction, for example, is distinctive in that it works in residential, commercial, and industrial construction.

NANA’s Big Lake fabrication facility includes four buildings on 32-plus acres, with 105,000 square feet of indoor fabrication space. The site includes a prep and coating shop; industrial fabrication and assembly shop; and a light modular fabrication building, among others.

The NANA subsidiary, which opened in 2008, has found success by pursuing business in all construction niches. “If the oil and gas industry is down, residential and commercial construction may be up, so it’s beneficial to be in both areas,” says Elvsaas.

Approximately 95 percent of the company’s projects are competitively bid, though it may also receive projects from vendors or clients who reach out for their expertise. Depending on the project, fabricators may be brought in at the design/build stage, serve as the EPC (engineering, procurement, construction) contractor, or be asked to fabricate and ship previously engineered designs.

“It really varies by project; a lot of the time, we’re doing structural steel fabrication, like building 1,000 VSMs [vertical support members] or 400 HSMs [horizontal support members]; we also build a large amount of REIM [remote electrical and instrumentation modules] and pigging modules,” says Elvsaas, adding that the most intricate products the company fabricates are the fuel gas manifolds that are used in Prudhoe Bay.

Some of the more interesting projects that NANA Construction has been involved with include fuel gas manifolds for the compressor engines at the Prudhoe Bay central gas facility and a bar for the Norwegian Rat Saloon in Dutch Harbor.

“The compressor project was a challenge because it’s a huge circle with super tight parameters—and it took about three weeks of tweaking on it to make everything fit,” says Elvsaas.

Dowland-Bach

Dowland-Bach

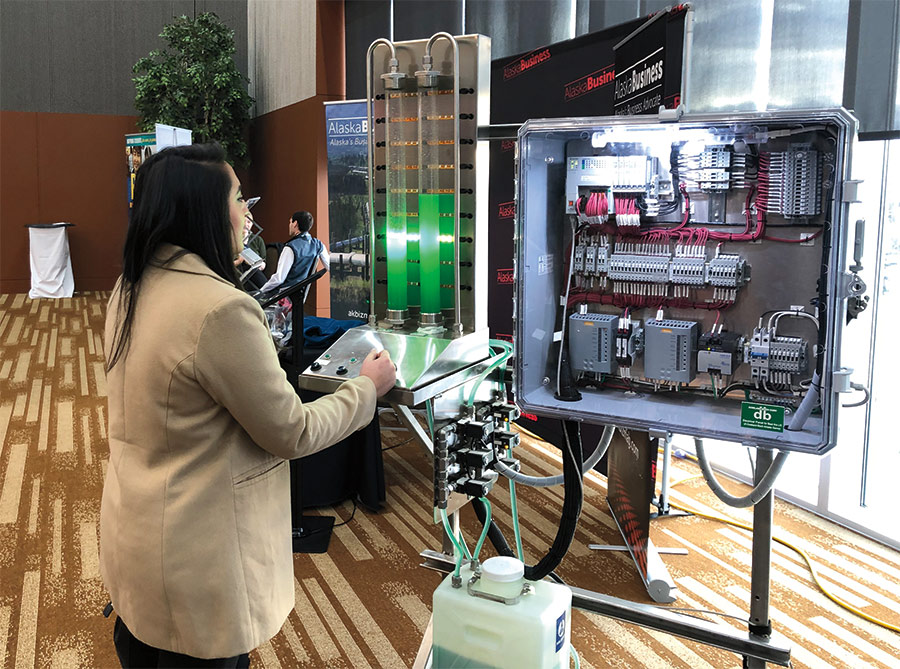

Dowland-Bach Corporation, located in Anchorage, manufactures end-use products for industrial companies and focuses on three core products: wellhead safety control systems for oil producers; UL-listed electrical control panels for general industrial applications; and chemical injection systems for oil, gas, mining, water, and wastewater applications.

“These are the bread-and-butter of what we do as a company,” says Vice President of Operations Tony DeHaven. “The high-pressure safety control systems are mainly built out of stainless steel and have quite a variety of pieces and parts that we fabricate in-house. We package these systems with valves and pumps and high-pressure accumulators together in a small form factor to save as much space as possible and still be easy to operate.”

Dowland-Bach buys many of the individual components from other distributors and does its own stainless-steel welding, tubing, and custom fabrication. The company recently invested in a high-powered laser engraver to engrave symbols and instructions onto the systems and to create custom engraved name plates.

“Our control panels come in a number of shapes and sizes, and we build them for a variety of Alaska-specific environments,” says DeHaven. “We are a UL [Underwriters Laboratory] 508A shop and that designation allows us to manufacture and supply control panels that meet state safety requirements and the national electrical code. In addition to that designation, we have twelve other NRTL [Nationally Recognized Testing Laboratories] and UL designations that enable us to build Arctic-grade panels or panels that can go into hazardous environments.”

The majority of these control panels are bought by oil and gas customers including ConocoPhillips, Hilcorp, and BP. “ConocoPhillips, for example, might order a large control module, so we’ll work together with other fabricators in Alaska to build a 50-foot building that can be put on a trailer and shipped to the North Slope, and we’ll outfit it with several control panels and telecommunications cabinets inside,” says DeHaven.

“Our control panels are all custom-made because every process is different,” he adds. “The panels are going into specialized environments that require certain ratings—for example, hazardous spaces with gas or chemicals or extreme air temperatures—so we pick materials and components that are safe to use in that space. There might be 100 different things that need to be controlled by the panel, which also determines what kind of controls we use.”

DeHaven says the company primarily serves industrial clients, as its panels are too specialized for standard commercial buildings, which rarely require complex process control functions.

Dowland-Bach

Dowland-Bach

Dowland-Bach

Dowland-Bach

“From the command center in Anchorage, Alyeska can control most of our control panels along the pipeline,” says DeHaven. “Our controls are also used in a lot of water and wastewater facilities; for example, Anchorage Water & Wastewater Utility has one or more of our systems in almost every one of their water processing facilities.”

One of Dowland-Bach’s more challenging projects was the fabrication of five chemical injection trailers, which required outfitting 20-foot trailers from a local company with stainless steel chemical tanks, pumps, tubing, electrical controls, and pressure and flow transmitters.

“We manufactured these for ConocoPhillips so that they could haul them around to provide chemical injections into remote sections of pipelines to condition oil and gas to improve flow and stability,” says DeHaven. “It was a challenging project because it required a very unique design, which we created using Autodesk Inventor to make 3D models so that the craftsmen could build it. From start to finish, it took about six months.”

While some of Dowland-Bach’s work comes from The Plans Room and the Associated General Contractors of Alaska’s list of public bids, it also has many repeat customers.

“Probably about 25 percent of our business is related to public bid work, and we also have good relationships with almost every electrical contractor in Alaska, so they know to come to us if they’re bidding on a project and need a price on a certain piece,” says DeHaven. “Out of a 2,000-page document of designs and specifications on a public project, they may ask us to supply only what they need in chapter 29 for process controls and instrumentation.”

“We often fall into the subcontractor range,” he adds. “When North Pole Utility put in a $10 million liquid natural gas facility, we supplied a metering skid and a control panel to the project. If it requires any kind of process control related to a water, gas, or fuel facility, we’ll usually bid on just the parts we produce. Our customers come to us because you can’t just buy these things on the internet.”

NANA Construction

NANA Construction

Dowland-Bach

Dowland-Bach

“We have a pretty good-sized shop here, and a lot of machinery we can use for metal fabrication, including a 100-ton press break that we use to bend metal into a variety of shapes,” says DeHaven. “We can take a flat sheet of metal, bend it into an enclosure, and weld it shut. If a customer needs a 2 by 10 by 8-foot enclosure, it costs them $2,000 to ship it up from the Lower 48. We can make it here from flat metal stock and they’ll pay pennies on the dollar for shipping.”

Being familiar with remote locations and conditions is also a huge advantage, according to DeHaven.

“We can get out to remote sites much more quickly and easily than out-of-state companies, and we’re very familiar with making products designed using components rated for low temperatures or harsh environments,” he says. “A building control panel that works in Texas is going to look and work differently than one designed in Alaska. Producers on the North Slope, and contractors in towns like Utqiaġvik, have bought supplies from out-of-state companies and had to replace them in a couple years because they’re not made for this environment.

Dowland-Bach

Dowland-Bach

While these companies have a lot of Alaska-based knowledge, they still need to keep up with changing times.

“We’ve been fabricating metal going on forty-five years now and, in general, we make the same products today that we’ve always made. But at the same time, our processes are improving constantly,” says DeHaven. “We’ve bought machinery that allows us to do more and to be more efficient in what we make. As we’ve grown, our factory filled up with specialized tools and equipment, and now the things we used to do by hand we can do by machine with much more precise results; we can get things down to micrometer precision.”

He adds that because the technology within control panels is constantly changing with microprocessors getting smaller, faster, and better all the time, the company has to stay on the cutting edge of technology.

“Technology has changed a lot,” agrees Elvsaas. “We’ve gone from manual stick welding, which is now automated, to running flex core wire, which brings speed and productivity way up. Things are much more streamlined.”

As for training, much of the knowledge at Dowland- Bach has been passed down over the years.

“There are metal fabricating apprenticeships out there for certain trades, but because we specialize so highly, there’s not really a school that teaches what we do,” says DeHaven. “Our founder was a metal salesperson who sold valves and fittings, and he was self-taught; he learned how to do metal fabrication and then taught generations of others that came along. We have quite a few younger employees, and they learn side-by-side with the veterans here.”

NANA Construction also provides on-the-job training and recruits employees from the Alaska Technical Center in Kotzebue, the Alaska Vocational Technical Center (AVTEC) in Seward, and the Alaska Job Corps in the Valley.

“After taking kids out of AVTEC with their basic welding certification, we can train them to be oil field welders in three to four years,” says Elvsaas.

For those interested in metal fabrication, there are educational opportunities in Alaska. Northern Industrial Training, for example, offers a four-week fabrication welding course that includes fabrication cutting and shaping; joining fit up and alignment; mechanical cutting; oxy-fuel cutting; plasma arc cutting; reading welding drawings; and more. The UAF Community & Technical College also offers a year-long welding course that includes metal fabrication courses. ![]()