Resource Development Special Section | Arctic

Safety reminder built right into the drilling rig floor.

© ConocoPhillips

Staying Safe on the North Slope

Facing Arctic weather, heavy equipment, and wandering bears

By Julie Stricker

orking in Alaska’s North Slope can be challenging enough, but a few companies are taking that challenge a step further, drilling from manmade islands into promising basins miles off the coast. Going offshore adds a measure of remoteness and additional hazards to the workplace, such as floating ice, frigid water, and transportation by boat, hovercraft, or helicopter—or tracked vehicle after freezup.

It’s still Alaska’s North Slope, so it’s dark for months at a time. Blizzards bring high winds, stinging snow, and wind chills that in 2014 dropped to 97 degrees below zero. Polar and grizzly bears roam the region. In the summer, mosquitoes descend in hordes, backed up by swarms of biting flies.

Despite these conditions, a strong safety culture keeps accidents low, says Dave Wulf, vice president of health, safety, and environment for ConocoPhillips Alaska.

“We pride ourselves on our safety culture,” Wulf says. “We’re never happy with our performance. We always want to get better. In the world of safety, until you can sustain that nobody gets hurt and there’s no injuries, you just keep trying harder and harder.”

Training on Training

For workers, safety begins before they ever step foot on the North Slope tundra or venture offshore from it.

In 1997, the North Slope Training Cooperative was created to develop high-quality standardized health, safety, and environmental training programs. The cooperative began as an agreement between BP and ARCO on basic safety requirements for workers. Today, member companies include BP Exploration (Alaska); Caelus Energy Alaska; ConocoPhillips Alaska; Eni Petroleum; ExxonMobil; and Hilcorp Alaska, which fund the program. Contractors for these companies also support the cooperative.

Workers must complete a six-part, eight-hour training course, referred to as a six-pack, to receive their NSTC card, which allows them to travel on the Slope without an escort. Topics cover camp and safety orientation; environment; hazard communication; hazardous waste operations and emergency response (HAZWOPER); personal protective equipment; and the Alaska Safety Handbook.

The Alaska Safety Handbook—produced by the cooperative—covers a wide range of topics, including heavy equipment safety, weather contingencies, travel, confined space work, and flammable hazards. Drugs and alcohol are strictly prohibited in the oilfields.

“People have to be very aware of what’s going on around them. People take their eyes off the path just for a second and don’t see that tripping hazard, and they trip and they fall on the ice and end up with injuries that include broken bones… We’re really trying to focus in on the human and to keep people in the moment all the time.”

—Dave Wulf, Vice President of Health, Safety,

and Environment, ConocoPhillips Alaska

A construction crew prepares for the day ahead.

© ConocoPhillips

Offshore Circumstances

Most of Alaska’s North Slope oilfields are onshore. However, a few miles off the coast Hilcorp is producing oil at Northstar Island (developed by BP in 1999) and is planning a similar development at the Liberty prospect, six miles offshore east of Prudhoe Bay. Italian oil corporation Eni is working offshore on manmade Spy Island over its Nikaitchuq development, having drilled its first of four proposed wells in late 2017. Caelus Energy built Oooguruk, operated from a gravel island in Harrison Bay. All involve offshore gravel islands with oil transported to the mainland via buried pipelines.

There are a few specific safety concerns for offshore operations, covered in an NSTC offshore safety awareness course, which add another three to four hours to the basic NSTC requirements. However, safety recommendations are generally the same across the Slope, although workers on offshore platforms may be required to wear personal flotation devices and additional protective gear if they work near the water. A skiff and ring buoys are also required at the facilities.

Workers who are transported by helicopter must wear a Coast Guard-approved exposure suit, fully zipped and buttoned and equipped with a strobe light. Offshore safety awareness also includes an introduction to the lifestyle and culture of Alaska Native people who live along the Arctic coast, as well as the region’s unique geography, wildlife, and weather.

The Bureau of Safety and Environmental Enforcement oversees the offshore operations. On trips to inspect operations at Northstar, for instance, weather is the prime consideration. Even in summer, sixty degree morning temperatures can plunge thirty degrees in a few hours. Trips are planned up to two weeks in advance in order to catch a good weather window.

Gearing Up

That’s an issue onshore, too, says ConocoPhillips’ Wulf.

Between October and May, workers are required to carry Arctic-rated gear with them at all times. That includes a parka, insulated pants, Arctic-rated boots, gloves or mittens, face shields and goggles, and other survival gear. Many also wear traction devices on their boots in icy conditions.

“Let’s say you’re in a pickup and the pickup dies and you’re out in the middle of the tundra somewhere—you’re going to be able to survive those weather conditions,” Wulf says.

That’s standard across the North Slope. Notices are put up every year to remind workers to carry their Arctic gear. In addition, all workers are required to wear standard personal protection equipment such as a hard hat, safety glasses, hearing protection, and sometimes double hearing protection in areas with high noise levels. Flame-resistant or Nomex (a fire-resistant fiber that doesn’t melt or burn) clothing is also required.

Internal Programs

While all workers are required to undergo NSTC training, the individual companies working on the North Slope often have their own internal safety programs.

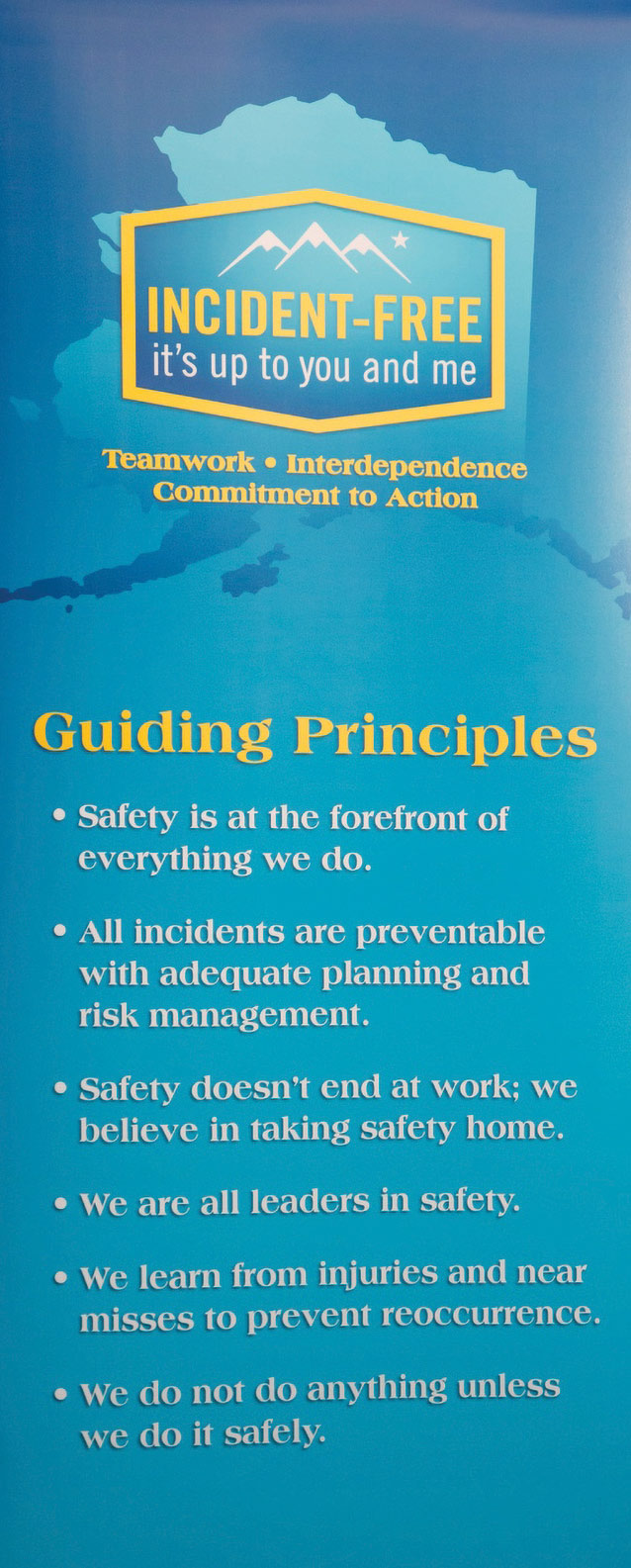

“[At] ConocoPhillips we pride ourselves on our internal incident-free culture,” Wulf says. “The motto we say is ‘incident-free, it’s up to you and me.’ The incident-free culture is our framework that puts a common language around HSE [health, safety, environment] not only for our employees but for our contractors.”

The company, Alaska’s largest oil producer, operates an internal program that employees must learn. It’s in the process of updating that program to add more content on human performance and learning organization, he says.

“That’s kind of our next step in our journey: what else can we do to improve our performance,” Wulf says. “We think it’s in that arena of focusing on humans, at how humans perform. And at the same time, looking at how well we really learn from incidents. So that’s the journey we’re on. That’s incident-free culture.”

Wulf says the biggest challenge is simply situational awareness.

“If you think about what we do, we do it in the worst months of the year as far as weather conditions,” he says.

Workers travel on ice roads. Winds can rise suddenly, causing whiteout conditions in which people have to just hunker down and wait for the wind to ease.

“People have to be very aware of what’s going on around them. People take their eyes off the path just for a second and don’t see that tripping hazard, and they trip and they fall on the ice and end up with injuries that include broken bones.

“We’re really trying to focus in on the human and to keep people in the moment all the time. It’s very hard to do.”

Construction crews perform calisthenics at their morning safety meeting.

© ConocoPhillips

Each oilfield is unique and presents different safety challenges. For example, ConocoPhillips’ Kuparuk field contains 1,000 wells with three central processing facilities plus a seawater treatment plant. The scale is far larger than at the company’s Alpine field, which contains about 250 wells and one treatment facility.

“It’s very easy for people to get their arms around Alpine in their daily planning; they can include everybody because everybody’s right there,” Wulf says. “Whereas as [at] Kuparuk, you’re spread out around the whole field.”

The Range of Hazards

ConocoPhillips’ drill rigs are enclosed and heated, so rig workers’ exposure to the environment is minimal. However, the safety training handbook does cover working in a confined environment and contingency plans for foul weather.

Workers who are transported by helicopter must wear a Coast Guard-approved exposure suit, fully zipped and buttoned and equipped with a strobe light. Offshore safety awareness also includes an introduction to the lifestyle and culture of Alaska Native people who live along the Arctic coast, as well as the region’s unique geography, wildlife, and weather.

Bad weather conditions are divided into phases, based largely on wind speed, temperature, and visibility.

![]() Phase 1 is cautionary and put in place when visibility is reduced. Travel is still permitted, with caution, and workers must wear full Arctic gear.

Phase 1 is cautionary and put in place when visibility is reduced. Travel is still permitted, with caution, and workers must wear full Arctic gear.

![]() Phase 2 is restricted to convoy traffic only. Vehicles must be in radio contact.

Phase 2 is restricted to convoy traffic only. Vehicles must be in radio contact.

![]() Phase 3 is restricted to critical or emergency traffic only. Travel by heavy equipment convoy only.

Phase 3 is restricted to critical or emergency traffic only. Travel by heavy equipment convoy only.

Weather isn’t the only hazard. The North Slope is home to a healthy population of both grizzly and polar bears, muskoxen, fox, wolves, and caribou. While caribou aren’t predators, they can still pose a hazard. In 2017, a plane that was trying to land at the Deadhorse airport had to take evasive action to dodge a caribou in the middle of the runway. The plane’s landing gear clipped the caribou, beheading it, but the plane circled and landed safely.

Polar and grizzly bears also pose a threat. Offshore and near the coast, polar bears may be drawn to the water by seals. On Northstar, fences and other physical barriers are used to keep bears away from the production facilities and workers. Thermal imagery cameras alert workers to the presence of bears. If a bear is seen, workers follow a standard protocol. First, they move to a safe place and alert security. Since polar bears are considered a marine mammal, only designated security officers with special training are allowed to deal with the bear. They use nonlethal deterrents, such as flashlights or air horns, escalating to beanbag rounds or rubber bullets to haze the bears into leaving.

Fairweather trains bear guards for oil companies and scientific excursions. Operations Manager Guy Miyagishima says bear encounters are relatively rare. While onshore polar bears rarely stray far from the coast, grizzly bears frequent the areas around the oilfields. In 2011, a polar bear was fatally shot when it approached employee housing at a BP Alaska site.

Wulf says ConocoPhillips hasn’t had any bear encounters in quite a while.

“I think the reason it’s so good is everyone is very respectful of wildlife and they get the right-of-way,” he says. “When we run into issues, whether its Arctic fox or red fox, people are very well trained that they need to notify [security], and there are procedures if we have to haze them. But it hasn’t happened since I’ve been around.

“I think we’re very proactive in wildlife management.”

Taking Care of Everyone

Bear awareness also protects the bears.

Anytime ConocoPhillips has to work out in the field in the winter, they fly in using forward-looking radar, which can detect polar bear dens in the snow when sows and cubs are hibernating.

“There are stipulations for when we’re putting in a pipeline and we come within so many feet of that den, we may need to re-route,” Wulf says. “So it’s very important we fly these things before we nail our plans down and are breaking stone.”

While the company culture includes rules for responsible and safe wildlife interactions, it also fosters a culture of teamwork and engagement.

Interpersonal conflicts, which seem likely considering the remote and enclosed environment, are actually rare. Wulf says he believes that is because of ConocoPhillips’ company culture.

A worker all geared up for winter construction including extra gear for visibility and warmth.

© ConocoPhillips

Wulf has spent thirty-one years with ConocoPhillips in different places. He’s only been in Alaska for two years, but he says the culture here is apparent.

“What has impressed me the most in the first year is the amount of teamwork, and I think it’s because we’re remote that we rely heavily on one another,” he says. “If we’re up on the Slope, I don’t know most of the time if I’m talking to a ConocoPhillips’ person or a contractor because they all blend in the same. Everybody is treated the same. Probably equally impressive is people are engaged. There have been times in my career where I’ve felt I’ve been trying to push safety down peoples’ throats, but in Alaska, people own it. And it’s real. You can feel it when you go out there.

“Although we’ve had ups and downs, they’ve never wavered on that. It’s the independence that Alaskans have compared to the Lower 48. We don’t have the luxury of just picking up and running down the street. So they have to make do a lot of times.” ![]()