fter years of planning and saving and months of watching construction progress, you have the keys to your new, custom-built home. It’s time to move in. Your internet provider is hooking up fiber to ensure everyone in the family will have fast, seamless internet for their various devices.

But wait, there’s a problem: the installation technician says running fiber to the interior wall where your media panel is located will mean stringing unsightly cable along the baseboard of your fit-for-a-magazine dining room. If only this could have been avoided!

Nash says the average home today has twenty-three devices connected to the internet. Planning for smart homes before construction is essential.

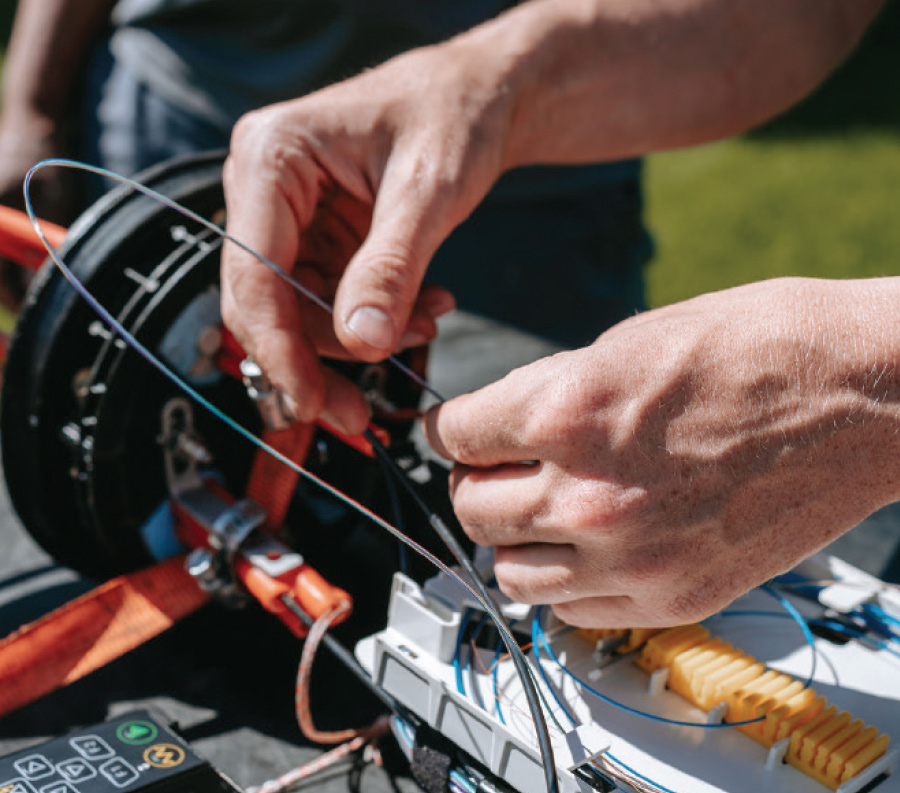

“If they wire for Cat6 (for ethernet or other network purposes), we want to make sure at the beginning they get a conduit from outside the house to wherever their media panel is going to be,” Nash says.

The media panel is where all telecom jacks are brought to a central location within the house, he explains. Having most devices function wirelessly makes wiring easier; generally, a house needs only one media panel. Nash says MTA can provide microduct conduits for builders to incorporate into walls, if the utility is consulted early enough in the process.

GCI

“What we really encourage is for developers to get in touch with us. We can let them know if we have fiber in the area or if we don’t; it helps us plan and prioritize our budget where we extend our fiber network,” Nash says. “[What] we’re asking them to do is, before they put the sheetrock on, get in touch with us. We’ll give them the microduct or conduit and ask them where they want to put the media panel. Then we can pull the fiber in or, if it isn’t available yet, we can pull the Cat6 in. There’s nothing worse than someone spending $500,000 to $600,000 on a home and then you go stapling stuff up on the outside.”

Nash underscores that the process generally works smoothly. MTA works with a lot of builders, he says, and many of those builders build a lot of homes; in its Matanuska-Susitna Borough service area, many builders develop whole subdivisions and focus less on homes on scattered lots. For the most part, MTA has an open dialogue with those developers and works to get fiber to the new “greenfield” subdivisions quickly.

Rebecca Gamble, president of Hall Quality Homes, says her company typically works that way. Fiber is planned for the whole development so it’s ready to be brought into homes when MTA extends it, if it’s not already available. If the house has a buyer when it’s being built, placement of the media panel is discussed. If it doesn’t, she says, the media panel generally goes in the most ideal place, typically in the attached garage, and always with a Cat6e cable running to the router.

As president of the Mat-Su Homebuilders Association, Gamble adds, “We all have a good relationship with MTA, and they are always willing to work with us to get the best service possible.”

Alaska Communications

Explaining the second, Olewniczak says older homes generally lack structured cabling systems, “forcing installers to either leave the router in one spot and strengthen the signal via WiFi extenders or retrofit wiring in walls, which can be both costly and invasive. To avoid this issue, builders should install empty conduits with pull strings between key areas, making future cable runs simple. Alternatively, they could run Cat6a or Cat7 ethernet cables, making work for installers extremely easy and ensuring the home is future-proofed.”

For new home construction, Olewniczak, like Nash, suggests installing conduit from the street to a structured wiring panel inside the home, designing a location for the media panel—perhaps in a utility closet to keep appearances tidy—placing Cat6a or Cat7 high-speed cable and jacks in every room (especially rooms that might have televisions, home offices, or other smart devices) or installing conduits with pull-strings in walls and ceilings to make this possible, and pre-wiring Power Over Ethernet or capable ethernet ports to support smart devices such as cameras, access points, and Voice over Internet Protocol phones.

If that doesn’t happen? The Alaska Communications team can handle minor retrofits such as drilling holes between the ground floor and a crawlspace or attic, but “as much as we would like to do whatever we can to deliver service to our customers, we are not specialized in completing medium to large structural changes around customers’ homes, like cutting into walls, adding power outlets, jacks, et cetera,” he notes.

Alaska Communications operates a statewide data network and a diverse undersea fiberoptic system connecting Alaska and the rest of the United States. It has participated since 2017 in the Federal Communication Commission’s Connect America Fund Phase II universal service for high-cost areas program in Alaska, deploying high-speed internet to nearly 30,000 locations in Alaska, including Coffman Cove, Delta Junction, Homer, Hope, Hoonah, Kake, Kasilof, Kenai, Klawock, Larsen Bay, Ninilchik, North Kenai, North Pole, Seldovia, Soldotna, and Sterling.

MTA

Meanwhile, MTA is working to distribute fiber throughout its service area. The company installs an average of 140 miles of fiber a year, Nash says.

“Our goal is to get fiber to homes everywhere, and especially to businesses,” he says.

Everywhere, for MTA, means in Mat-Su, Chugiak/Eagle River, and subscribers in the Beluga/Tyonek area, starting this year. Funded by a $12.5 million 2023 ReConnect grant from the US Department of Agriculture (USDA), the project—in cooperation with the Native Village of Tyonek—will lay 41 miles of transport fiber from Point MacKenzie to Beluga and Tyonek, then extend that fiber into 144 residential locations, 14 businesses, and 1 educational facility in Tyonek. Nash says crews were in the field trenching the transport lines in March while the usually swampy, wet ground was frozen. The company hopes to wrap the project up by the summer of 2026.

Alaska’s largest telecommunications provider, GCI, has been working to bring fiber to rural Alaska communities, most recently through its AU-Aleutians Fiber Project, a more than $100 million project funded in part by a $25 million USDA ReConnect grant, a $29.3 million grant from the National Telecommunications and Information Administration Tribal Broadband Connectivity Program, $5 million in USDA Rural Development Community Connect Program funding, and more than $50 million in private funding from GCI that will ultimately lay an 800-mile subsea fiber optic backbone, from which high-speed internet has already been delivered into homes in Akutan, Chignik Bay, King Cove, Larsen Bay, Sand Point, and Unalaska. Port Lions and Ouzinkie are next. Local fiber will also be built in Chignik Lagoon, Chignik Lake, Cold Bay, False Pass, and Perryville as part of the project.

Jones says it would be great to be able to sit down—utilities, developers, and others who might be making decisions about utility routing—and try to map out what’s happening, ideally five or six years down the road.

Gamble says planning that far ahead is difficult. Land in Mat-Su is free-market, so what becomes available and developable can change within a short timeframe. “I’m not sure about next year at this moment,” she says.

Wherever new homes are being built, service providers have forms on their websites where developers can send requests for service and notices of construction, and experts are available to provide guidance on future-proofing homes with the latest technology.