ydrocarbons are a two-edged sword. One edge is hydrogen, storing energy like wound-up springs that is released when combusted with oxygen. The other edge is the carbon atoms the hydrogen is bonded to, which in the grip of oxygen become a climate-warming veil of carbon dioxide gas. Petroleum under the North Slope and methane under Cook Inlet have both potentials: productive energy from hydrogen and destructive pollution from carbon. In a decarbonizing global market, Alaska needs a way to separate the good from the bad.

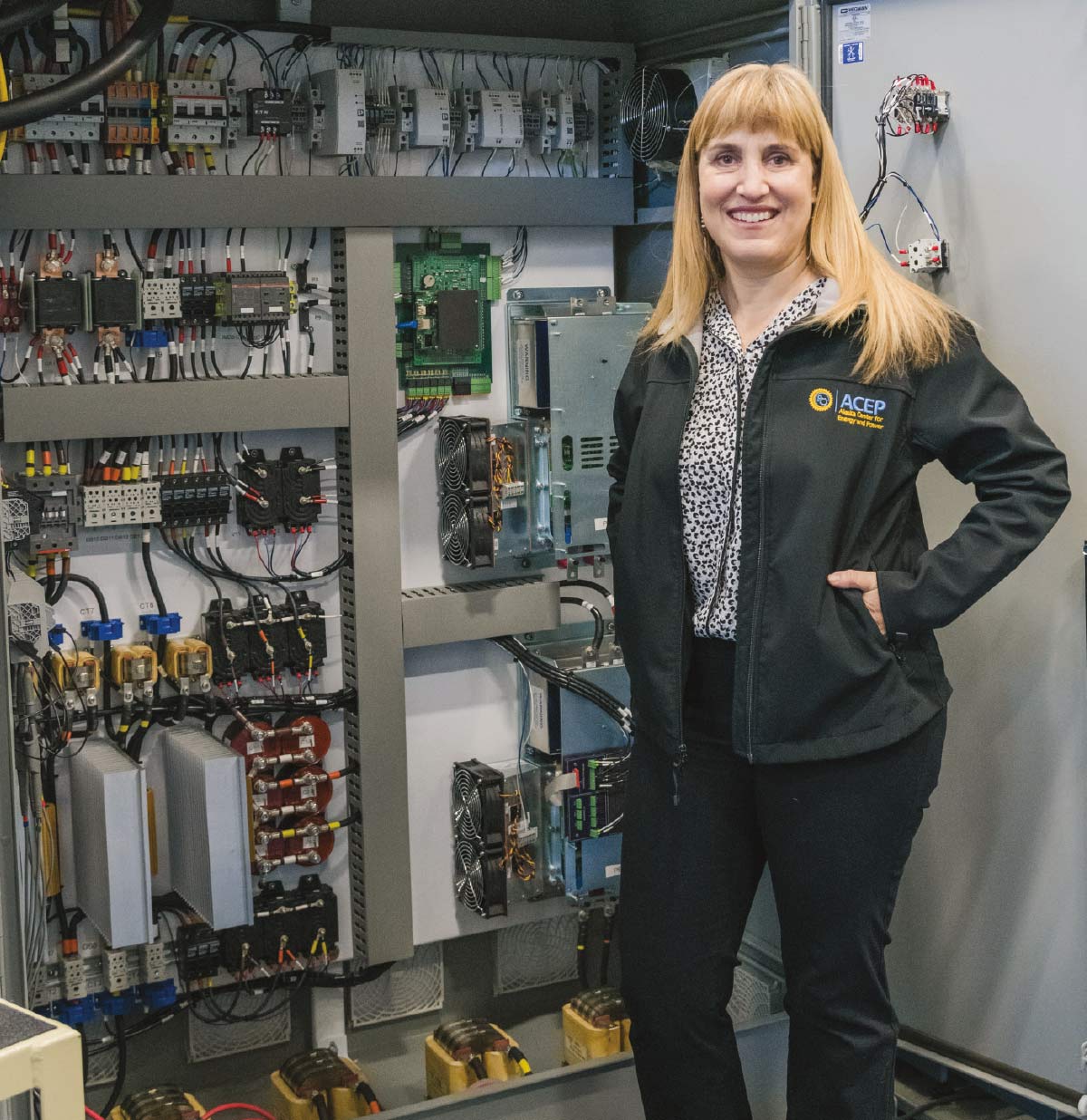

“If we want to continue to be an energy exporting state, which is very much what we see ourselves as, we need to understand those markets are changing internationally,” says Gwen Holdmann, director of the Alaska Center for Energy and Power (ACEP) at UAF.

The fastest change is in maritime shipping. Last year, the Marine Environment Protection Committee of the International Maritime Organization adopted its MEPC 76 amendment, which requires large ships to be rated for carbon intensity, starting next year. The quickest path to reduced carbon intensity is burning fuel without carbon in it.

“Ammonia is probably the leading candidate for them,” Holdmann says.

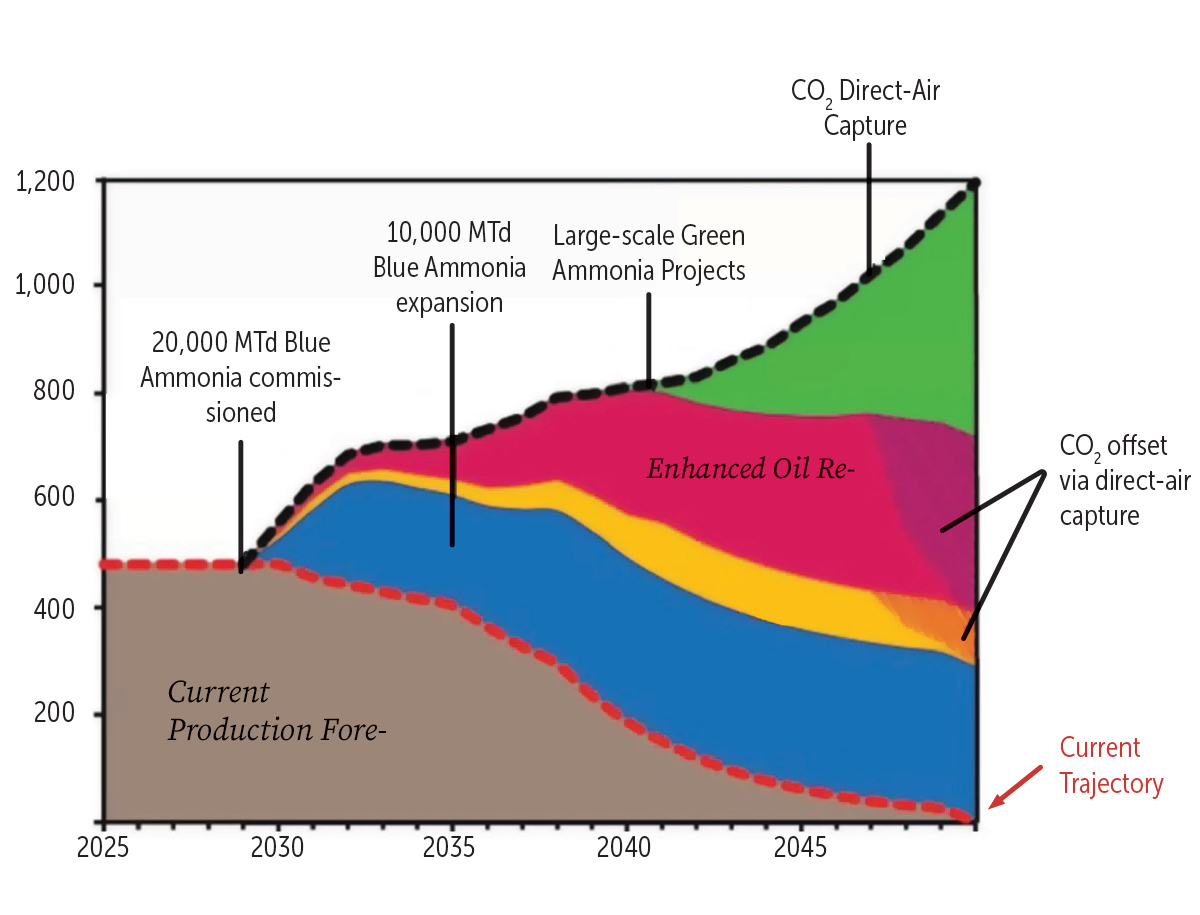

The International Energy Agency forecasts up to 10 percent of global shipping will use ammonia fuel by 2040 to satisfy the MEPC 76 standard. Within fifty years, the projection is 70 percent.

On shore, South Korea and Japan set targets of net-zero carbon emissions by 2050, followed by China’s goal of net-zero in 2060. Japan’s largest electric utility wants ammonia to replace coal in its power plants. That shift requires a new marketing approach for the Alaska Gasline Development Corporation (AGDC) as it tries to sell liquified natural gas (LNG) from the North Slope to Asian utilities.

Prior to 2013, South Korea did import ammonia from Alaska, made at the Kenai Nitrogen Facility in Nikiski. It was sprayed into dirt as plant food.

“Ammonia has always been sold for its nitrogen value; people pay for what it’s worth as a fertilizer,” says chemical engineer Nathan Prisco. “And then [Japan] realized, just a few years ago, ‘If we burn it, we already hit our hydrogen target.’ The hydrogen value of ammonia had been undervalued.”

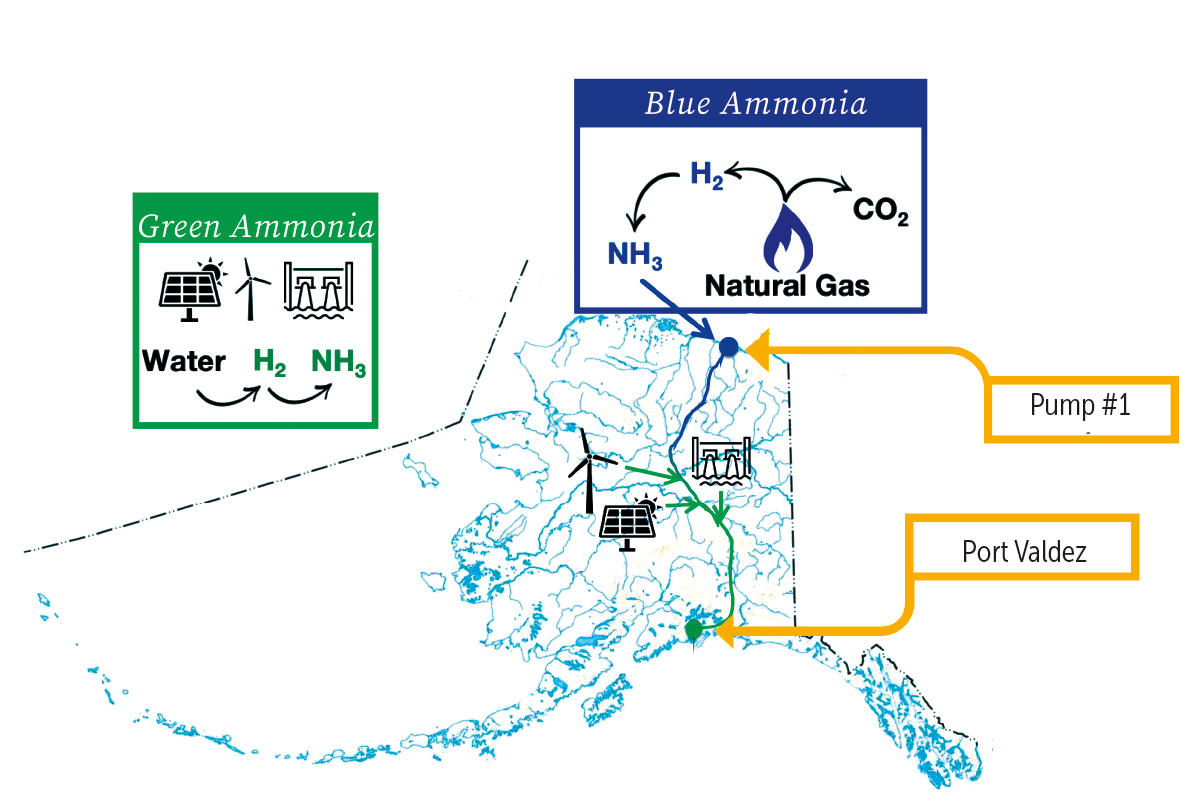

Anyone selling hydrocarbons needs a “credible energy transition story,” says Nick Szymoniak, AGDC’s manager of new business ventures. Alaska has that story, he says: “Alaska, by geologic dumb luck, has a great carbon sequestration basin in Cook Inlet. By a history of industrial dumb luck, we have an existing ammonia plant sitting idle. And based on geography dumb luck, we’re located in close proximity to Asia.”

Mighty Pipeline

Mighty Pipeline

Nikiski is AGDC’s choice for the terminal of its AK LNG pipeline, which could revive the fertilizer factory next door. To the extent that North Slope natural gas itself is a low-carbon alternative, Richards explains that the mixture of gasses out of the ground includes about 10 percent CO2. The carbon dioxide can be separated from methane and reinjected, just as natural gas is currently put back in the ground to repressurize oil reservoirs. That is why carbon emissions compare favorably to LNG from the Gulf of Mexico, according to a report AK LNG released last October.

Richards says that makes Alaska LNG one of the best bets in the world, in terms of low carbon intensity.

For lower intensity, carbon capture and sequestration (CCS) can, by the same principle, trap CO2 emissions from an ammonia factory. In the color scheme of ammonia production, this is “blue.”

Although the Nikiski fertilizer factory never captured its carbon, the potential is there. “The Cook Inlet basin, not only with its depleted oil and gas reservoirs but with its immense coal bed seams, has the greatest opportunity for carbon sequestration of any basin on the Pacific West Coast,” says Richards. Holdmann agrees Cook Inlet is a pretty good CCS basin.

Now, what if the ammonia factory were on the North Slope? That’s what Prisco is proposing.

Prisco is the first Arctic Innovator, a program sponsored by the US Department of Energy (DOE). The award allows Prisco to split his time between Pacific Northwest National Lab in Richland, Washington and UAF’s Center for Innovation, Commercialization, and Entrepreneurship (Center ICE). When he came to Alaska in 2021, he wanted to apply his PhD toward decarbonization.

Prisco recalls, “When I arrived in Fairbanks, they walked me around the lake, and they’re like, ‘No, you’re starting a company!’”

His start-up, barely a year old, is aimed at transporting ammonia from the North Slope. He named the company Mighty Pipeline.

Sarah Lewis

Sarah Lewis

Sarah Lewis

Sarah Lewis

Prisco had to be sneaky to outwit ammonia, coaxing it to blend with crude oil. “Emulsions are a very subtle art,” he says, so he looked to shampoo and lotion manufacturing for tricks to hold both liquids together.

The result is “mighty solution,” what Prisco calls the world’s first stable emulsion of ammonia and crude oil. “You might think of this like natural peanut butter which, over time, will separate into oil and protein components,” he says. “Basically, we have a low-cost, low-energy method of producing stable mixtures for use in pipeline and fuel systems.”

The Trans Alaska Pipeline System (TAPS), in particular—provided Alyeska Pipeline Service Company is convinced it can be done safely.

“We’ve had a few discussions with Alyeska,” Prisco says, “and it’s about as useful as saying, ‘What do you think about ghosts?’” He says the oil industry is wary of ammonia; a skill set built on hydrocarbons has little love for inorganic chemistry. Ammonia can also be corrosive, but Prisco says that shouldn’t be a problem for TAPS because the oil emulsion protects the steel. Alyeska had no comment.

Only a fraction of North Slope gas might be sent down TAPS this way, says Mighty Pipeline Chief Operating Officer Ky Holland. “The North Slope is currently producing such an incredible amount of natural gas and reinjecting it that… you could put another ten projects in there, and we could all stay busy,” he says. AGDC agrees there’s no competition with AK LNG for gas supply.

By the way, Holland used to work in the sewer business, so when it comes to the pungent aroma of ammonia, he has a simple philosophy: “Smells like money.”

In dollar terms, Prisco estimates about $10 billion would be needed to build an ammonia factory on the North Slope and, crucially, to “recalibrate” TAPS to accept the emulsion. That compares to nearly $40 billion for AK LNG. If successful, it could add 120,000 barrels per day to the pipeline, now carrying about 500,000 barrels per day of crude, or one-quarter of its maximum capacity.

Mighty Pipeline will begin a Phase 1 demonstration this summer at UAF. One person awaiting the results is Bill Leighty, a Juneau-based inventor who’s been working on ammonia energy for decades. Leighty calls Prisco “the perfect guy to pursue it,” yet he has reservations about the Mighty Pipeline approach.

“Assuming that we capture every molecule of CO2, give it back to them, and they inject it underground for enhanced oil recovery, now we have accomplished blue ammonia—but for the purpose of producing more oil so we can burn it and put more CO2 in the atmosphere,” Leighty says. “What color ammonia is that?”

In 2013, Leighty intended to use a $750,000 state grant to build a mobile, kilowatt-scale pilot plant to demonstrate production, storage, and energy recovery from ammonia. Suffice to say, that never happened.

“The ammonia industry has leapfrogged, as hydrogen has, beyond my usefulness,” he says.

Major institutes are trying to solve the green ammonia problem through DOE’s Advanced Research Projects Agency-Energy (ARPA-E) and its REFUEL program, which stands for Renewable Energy to Fuels through Utilization of Energy-dense Liquids. ARPA-E program director Grigorii Soloveichik says megawatt-scale green ammonia facilities are on the drawing boards in Australia, Chile, and Oman. What’s held them back has been the integration of continuous ammonia production from intermittent wind and solar. But the principle is sound.

“You can convert existing infrastructure to run off of either 100 percent ammonia or high proportions of ammonia, so it’s one of the few things that can be a replacement fuel,” says Holdmann. In fact, she collaborated with Szymoniak on a 2008 study into ammonia fuel for rural Alaska. They concluded ammonia wouldn’t be economic until wholesale diesel was at least $8 per gallon.

Ammonia of any color can’t compete with hydrocarbons on those terms. Fossil fuels are energy-dense and synthesized for free in the ancient geologic past. Synthesizing ammonia consumes energy; combining nitrogen with hydrogen costs more energy than it releases.

“Round-trip energy efficiency for ammonia produced from excess renewables, delivered to market, you’re getting about 30 percent,” says Prisco. “You always lose when you convert.”

Leif Van Cise | UAF

Leif Van Cise | UAF

Carter Damaska | Alaska Business

Carter Damaska | Alaska Business

UAF

UAF

Mighty Pipeline’s Holland sees the same possibility for Alaska. “Now you don’t necessarily have to ask the question, ‘Can we use that much energy in Alaska?’ Now we become a vehicle to be able to move that stranded energy to the markets that need it, in a form that they require.”

Leighty points out that Norway pioneered ammonia synthesis in the ‘30s because of that country’s plentiful hydropower. Nearly a century later, Norway’s dams still make ammonia (for fertilizer) by running continuously at night, when electricity demand is lower. “The marginal cost of that energy is zero,” Leighty says, “so why not do something useful with it?”

Ammonia could fuel village power stations, snowmachines, or ATVs. Leighty notes that electric aircraft are scaling up, with two-seaters currently powered by hydrogen fuel cells. Maritime fuel could be synthesized from offshore wind farms in the Aleutians, already abuzz with fishing fleets and cargo ships. Holland suggests harnessing water currents through False Pass or in the Yukon River, places with immense power but not enough people to use it.

Why stop there? Geothermal power, tidal generators in Turnagain arm, small nuclear reactors—any excess electricity can be monetized and transported as ammonia. The prospects are intoxicating. And then sober reality sets in.

“Alaska’s not set up to do [green hydrogen] in a big way today,” Holdmann says. “We certainly have renewable resources that we could develop, but that’s not going to happen tomorrow.”

Chief Operating Officer and Co-Founder

Mighty Pipeline

“It’s easy to say ‘Hey, we should be doing more of this,’ but if nobody is willing to actually invest in moving us in that direction, it’s pretty hard for people to figure out how to get there,” Holdmann says.

More money is becoming available, thanks to the Infrastructure Investment and Jobs Act, which allocates $8 billion for Regional Clean Hydrogen Hubs, another $1 billion for a Clean Hydrogen Electrolysis Program, and $3.5 billion for CCS. Other states have begun bidding for the federal cash. Senator Lisa Murkowski said in September that Alaska has “an enviously complete checklist” to grab a share, too.

Holland puts it this way: “Our energy legacy is not over if we move into this carbonless world. We can use this as a way to step into that new world, to build upon the best of what we’ve done, to be able to create something the world needs in the future.”

No single organization has all the answers for green ammonia right now, Holdmann says. “We all have a little piece of it, and we’ve all kind of dabbled in it here and there,” she says. “So now how can we get a little bit more serious about what that looks like today?”

The answer to “how” may be on the same floor of UAF’s Engineering Learning and Innovation Facility that Holdmann’s ACEP shares with Center ICE, where Prisco is halfway into his two-year Arctic Innovator award. Prisco, Holland, and their mighty colleagues have spent nearly a year looking for buyers of ammonia shipped out of Valdez—a much harder sell than when TAPS opened the spigot on Alaska’s hydrocarbon wealth in 1977.

Although ammonia fuel is a limited market now, it can only expand as carbon goes out of fashion. Prisco conjures a dream of Alaska villages storing energy in ammonia tanks, like firewood stacked for winter. In subzero weather, ammonia stays liquid without being pressurized.

“There’s very few places in the world where in winter you can walk around and borrow a cup of ammonia from your neighbor,” Prisco says. “Alaska is one of those places.” ![]()